Steel Gauge 101: Choosing The Right Frame For Your Garage

December 1, 2025

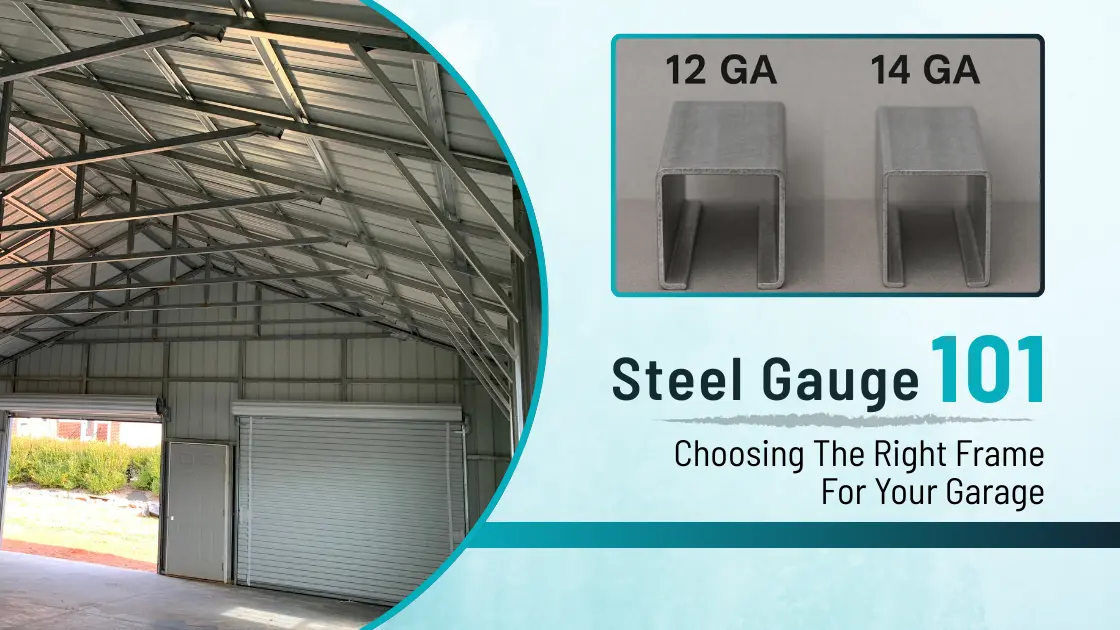

When you look at a metal garage, you mostly notice the roof and siding, but the real strength is hidden inside. It’s the steel frame that is the backbone of your building. It holds everything together and keeps it standing through storms, heat, and time. One of the most common questions we hear is, “What’s the right steel gauge (thickness) for my garage?”

This guide will walk you through the two most popular frame types-

- 12-gauge steel (thicker and stronger)

- 14-gauge steel (lighter and more budget-friendly)

We will start with what gauge means, compare costs, pros and cons, and help you pick the best fit for your metal prefab garage, climate, and long-term goals. So, let’s begin!

What Is A Steel Gauge In A Metal Prefab Garage?

What Is A Steel Gauge In A Metal Prefab Garage?

It’s a way to measure how thick a piece of steel is. The lower the gauge number, the thicker and stronger, heavier, and more durable the steel is. Think of it like a shotgun shell, 12-gauge is thicker than 14-gauge, even though the number is smaller.

- 14-Gauge Steel Frame – With a thickness of 0.078125 inches, it is the standard for most metal garages and residential buildings. It is great for mild climates and basic storage needs.

- 12-Gauge Steel Frame – With a thickness of 0.109375 inches, it’s a premium option and ideal for harsh weather, heavy-duty use, and most commercial setups.

In fact, the 12-gauge steel building’s frame is about 40% thicker than 14-gauge steel. This means 12-GA is thicker, has higher strength, especially against wind, snow, and long-term wear.

Why Steel Gauge Matters?

In short, steel thickness affects how long your garage lasts and how well it handles stress. A thicker steel resists bending, rust, and damage over time, so it’s not about the cost, but about protecting your investment and selecting what works best for your climate and use case.

What Is A 14-Gauge Tubular Steel Frame?

A 14-GA steel is the most common choice of framing for metal garages and carports. It’s thinner than 12-GA but still strong enough for everyday use.

What Are The Pros Of 14-GA Steel Tubular Frames?

- Cost-Effective – It is a more cost-effective steel frame option, especially for homeowners on a budget.

- Works Well In Mild Climate – It is perfect for areas with gentle weather throughout the year.

- Ideal For Small Metal Buildings – A 14-GA frame is great for one car garage, 2-car garage, and up to 24 ft. wide garage buildings.

- Easy To Install – Since it is lightweight, it’s easy to handle during setup and is DIY-friendly as well.

What Are The Cons Of 14-GA Tubular Steel Frames?

- Not Built For Harsh Weather – It can bend or flex under heavy snow, strong winds, or earthquakes.

- Not Suitable For Oversized Or Certified Buildings – It may not meet your local building codes, especially in stricter zones prone to flooding, hurricanes, and regions like tornado alley.

- Less Long-Term Durability – Thinner steel may wear faster with time.

What Is The Cost Of 14-GA Steel Tubular Frames?

A 14-gauge frame can cost about $3.96 to $4.50 per sq. ft. and has a weight-bearing capacity of 3.04 lbs. per sq. ft.

What’s A 14-GA Steel Tubular Frame’s Best For?

- It is most useful for homeowners who need a reliable garage without overspending.

- It suits a 1 or 2-car parking garage or small sheds for light storage.

- It’s best for southern states and areas with low snow and wind risk.

What’s A 12-Gauge Steel Tubular Frame?

It’s thicker and stronger than 14-gauge and built for tough jobs, harsh climates, and buildings that need to last for decades. It offers heavy-duty strength for serious protection and long-term use.

What Are The Pros Of 12-GA Steel Frames?

Here are some benefits of choosing 12-GA steel structures, have a look:

- Superior Strength – Thicker steel is better at resisting bending and warping, and it can withstand impact damage more effectively.

- Handles Harsh Weather – It’s ideal for areas with snow loads, hurricanes, or high winds.

- Required For Certified Buildings – Many states’ building codes require 12-GA for engineer-approved metal structures. So, you may be asked to choose one.

- Great For Commercial Use – It’s great for RV garages, workshops, and tall buildings.

- Offers Long-Term Value – Some manufacturers may provide you with a 20+ year warranty against rust-through with 12-GA steel.

What Are The Cons Of 12 GA Steel Tubular Framing?

Higher Upfront Cost – It costs more than 14-gauge but is worth it for its durability and code compliance. It may add about 15 to 25% to your total building cost, though.

Heavier Frame – Since thicker frames are heavy, they require professional installation due to weight and complexity.

How Much Does A 12-Gauge Steel Frame Cost?

A 12-gauge frame can cost about $4.50 to $5.00 per sq. ft. and has a weight-bearing capacity of 4.27 lbs. per sq. ft.

Who Is It Best For?

- You can use it for workshops, commercial storage, or storing high-value equipment.

- It is ideal for 30 ft. wide metal structures or larger units with tall legs.

- It works best for regions like the Midwest, the Carolinas, Texas, and anywhere with snow, storms, or high-speed wind risk.

A Quick Comparison Between 12 Vs. 14 Gauge Steel Framing

| Features | 12-GA Steel | 14-GA Steel |

| Thickness | 0.109375 inch | 0.078125 inch |

| Strength |

|

Standard, with some flexibility under load |

| Weather Resistance | Excellent | Fair |

| Cost | High upfront cost | Low, budget-friendly |

| Best Use |

|

|

| Common Applications |

|

|

| Warranty* (typically) | 20 to 25 years against rust-through | 10 to 15 years against rust-through |

*NOTE: The warranty may vary with the manufacturer, type, and size of the steel building you choose.

2 Must-Haves For Your Metal Custom Garage

When choosing steel frames, here are a few things that you must take care of:

1. Galvanized Steel Framings:

Both ’12’ and ’14’ gauge frames are available in 100% galvanized steel for modern metal garages. It is coated with molten zinc that creates a layer against rust, pests, and peeling. Galvanizing makes steel stronger and last longer than painted steel, especially in humid or coastal areas.

2. Certified Building:

Many states require 12-gauge steel for buildings that require engineering certifications. These certificates help with insurance, resale value, and safety compliance. So, it is best practice to always check local building codes before choosing your garage’s frame, especially if you live in windy or snowy areas.

Don’t Guess Your Metal Garage Gauge, Build Smart From The Start

Choosing between 12-gauge and 14-gauge steel depends on two things-

- Where do you live?

- How do you plan to use your garage?

If you live in a place with a mild climate and need basic storage or parking, a 14-gauge steel frame is a smart & cost-effective choice. And for places with heavy snow, strong winds, extreme heat, or large metal structures, go with 12-gauge, which is thicker, tougher, and last for decades.

So, don’t just look at the price, think about weather, usage, and future upgrades because the right steel gauge will give you peace of mind, offer better protection, and will be ready for anything you want. Still confused? You can talk to our metal building experts to learn more.